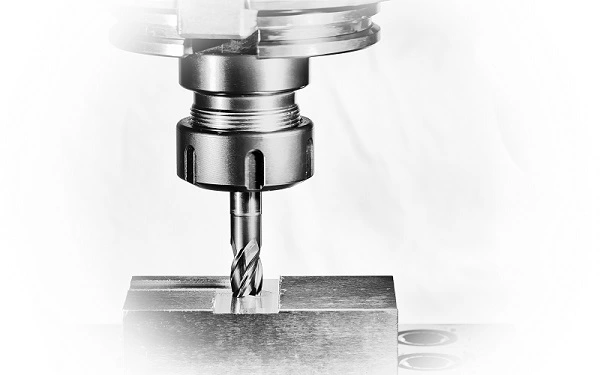

Online CNC Milling service

Looking for a qualifed, quick-turn CNC milling supplier? BERGEK CNC is your trusted CNC miling service company, providing high-quality turned parts.

With 15+ years of experience, we have the expertise to deliver complex CNC-turned parts. We can manufacture parts ranging from a few millimeters to large parts up to 1500 mm in length and 700 mm in diameter. We is definitely a great choice for custom metal and plastic machined parts. We own CNC machining factories, which are set up for rapid prototyping and production part machining. Try our online CNC milling services today!

● Complex project lead times range from 1 to 2.5 weeks.

● Over 50 metal and plastic materials available.

● Tolerance: +/- 0.05mm or better upon request.

● ISO 9001 certified.

Get A CNC Millining Quote!

Types Of CNC Milling Operations

CNC milling can produce a wide variety of features and shapes. This manufacturing technology achieves this through a series of specific motions and cutting techniques known as milling operations. The most common CNC milling machine operations are:

Custom CNC Milling Service - One Stop Solution

Get instant quotes for precision milled custom parts. Our customer service team will work with you to ensure your design specifications are met. Order your parts easily by following these steps:

Create or Upload Your CAD File – Design your part using our free CAD software or upload your CAD file, PDF drawing, or image.

Create or Upload Your CAD File – Design your part using our free CAD software or upload your CAD file, PDF drawing, or image. Configure Your Part – Choose from over 50 materials and finishes. Enter quantity, address, and any special notes for your machinist.

Configure Your Part – Choose from over 50 materials and finishes. Enter quantity, address, and any special notes for your machinist. Receive a Quote – Get a quote for your design instantly with our CAD software.

Receive a Quote – Get a quote for your design instantly with our CAD software. Order Your Part – Place your order and receive your high-quality CNC parts!

Order Your Part – Place your order and receive your high-quality CNC parts!Common CNC Milling Materials Selection

CNC milling processes are suitable for a wide variety of materials, including wood, acrylic, stone, glass, foam, ceramics, plastics, and many metals. Wood, stone, and glass are rarely used for industrial CNC milling. These CNC milling materials are primarily used for art, decorative, and home furnishing applications. On the other hand, many industries use metals and plastics for a variety of products. These CNC milling materials encompass a wide range of elements, compounds, and alloys, each with varying properties and applications.

| CNC Milling Metals | CNC Milling Plastics |

|---|---|

| Aluminum | ABS |

| Stainless steel | Polycarbonate (PC) |

| Brass | Polypropylene (PP) |

| Copper | Polyethylene (PE) |

| Titanium | PTFE (Teflon) |

| Mild steel | Carbon Fiber |

| Alloy steel | Nylon |

We offer a wide variety of CNC-machined metal and plastic part options, ready for instant online quotes. If you don't see the material you need in stock, please specify "Custom" in the material drop-down menu on the quote page and submit your request with the specified characteristics, tolerances, inspection requirements, and quantity for our experts' engineering review.

CNC General Tolerances

We will work to achieve and hold the tolerances noted below, which will vary per the primary manufacturing method you select.(eg.:Round hole 10mm, tolerance +0.01—0.03mm)

| Description | General Tolerance |

|---|---|

| Distance Dimensions | For features of size (length, width, height, diameter) and position (location, concentricity, symmetry), ±0.005". |

| Orientation and Form Dimensions | 0-12 inches: ±0.005", with a 1/2 degree tilt. For sizes 24 inches and above, please refer to PCBWay's manufacturing standards. |

| Edge Conditions | By default, sharp edges are broken and deburred. Critical edges that must remain sharp should be noted and documented on the drawing. |

We customize CNC Milling parts to meet your needs

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.

| Department Headcount | 132 |

| Monthly Production | 100,000 units |

| Tolerance Standard | ISO-2768-M (for both metal and plastic) |

| Maximum Tolerance | ±0.0254mm (±0.001″) |

| Maximum Milling Width | 800mm (31.50″) |

| Maximum Machining Height | 800mm (31.50″) |

| Maximum Machining Depth | 200mm (7.87″) |

| Minimum Machining Dimension | 5mm x 5mm x 5mm (0.2″ x 0.2″ x 0.2″) |

| Maximum Machining Depth | 200mm (7.87″) |

| Fastest Delivery Time | 3-7 Days |

Why Choose BERGEK For CNC Milling Projects

As a leading CNC turning service supplier in China, BERGEK has delivered over 3,000 projects for over 750 of the world's leading companies. We offer a wide range of CNC turning services, utilizing the latest technology and experienced engineers to deliver the highest quality components. Our partners' advanced turning centers can perform a wide range of milling and drilling operations, ensuring we can meet the most stringent design requirements.

What Our Customers Say

These are some of the things our customers have to say about BERGEK CNC Milling. Over the years, BERGEK has been able to handle everything from the simplest to the most complex projects with ease, providing expert advice, reasonable pricing, and reliable turnaround times. Regardless of the size of your project, BERGEK can meet your needs. We highly recommend BERGEK to everyone; you won't be disappointed!

Resources for CNC Milling

CNC Turning FAQs

How do I get a quote?

The quickest way is to complete our online quote form. Alternatively, if you'd like to discuss your project before submitting a quote, feel free to contact one of our engineers at service@szbergek.com.

How long does it take to get a quote?

For most projects, we strive to provide you with a quote within 24 hours. However, if you submit a quote in the morning, we can sometimes provide a quote the same day. This is not the case with injection molding, where quotes can take longer than 24 hours.

How much does a CNC milling operation cost?

Many factors influence the cost of CNC milling, including raw material, part design, production volume, post-processing, and the type of milling machine used. Each stage plays a crucial role in the overall cost of a CNC milling project.

What thread sizes can you use?

ISO Metric threads (M3, M6, etc.), BSPT, BSP, UNF

What is your fastest lead time for CNC turning?

For small scale CNC projects for Al6061 we can manufacture in as little as 2 days as we have the material readily available in-house.

How We Do It Meet And Define Global

Contact us today to learn more about our machining services and capabilities and to help you move your project forward.

Copyright © 2022 SHENZHEN BERGEK TECHNOLOGY CO., LTD. - www.bergekcnc.com All Rights Reserved.